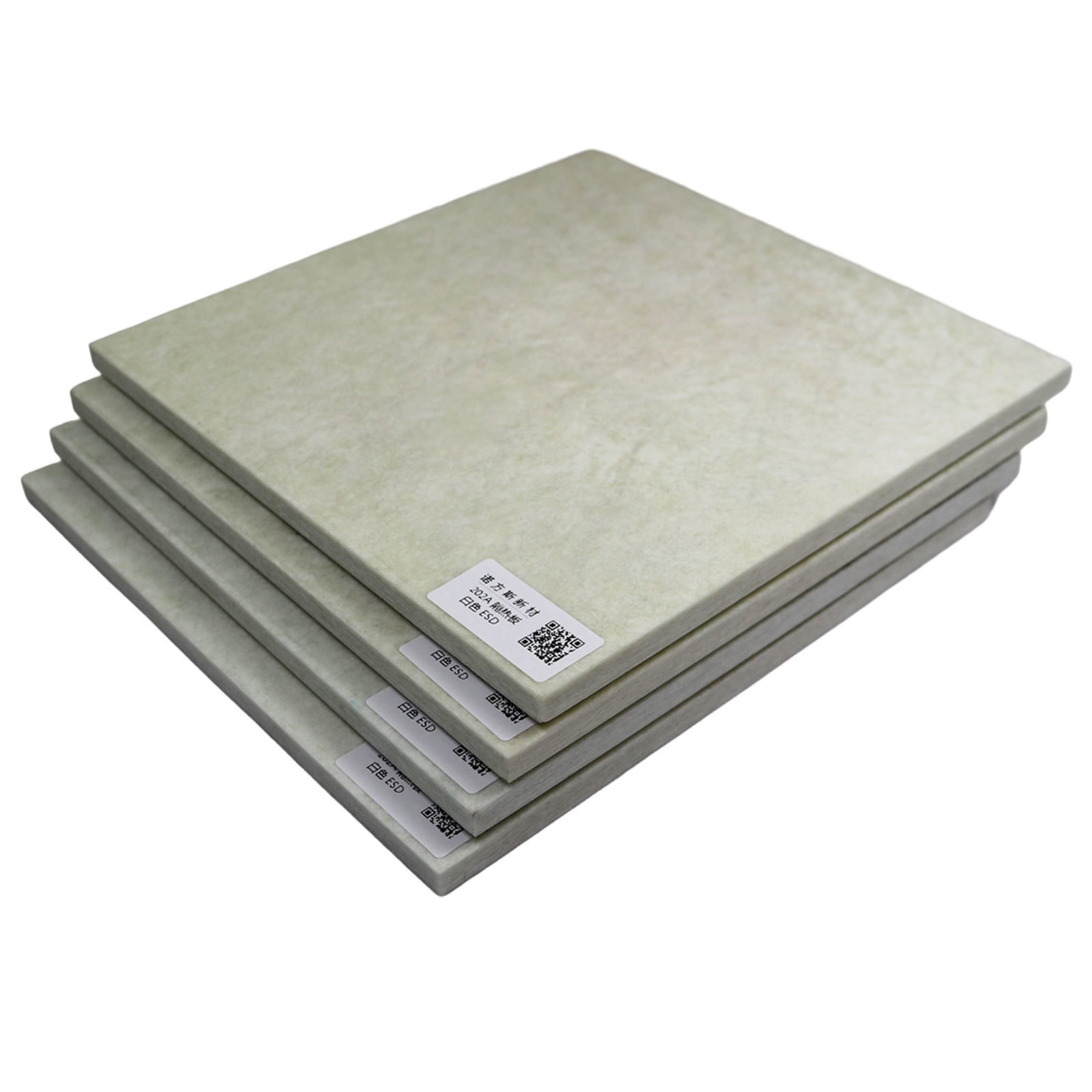

Introduction of Mold Heat Insulation Board

Time:

2024-12-12 16:47

Source:

Mold heat insulation board is a kind of material used between the mold and other equipments, which plays the role of heat insulation. The following is a detailed introduction about mold heat insulation board:

The main role of Mold heat insulation board

Molds in the working process, such as injection molds, die-casting molds, etc., often come into contact with high-temperature plastic melts, metal liquids and so on. Mold heat insulation plate can effectively prevent heat transfer from the mold to the mold mounting platform or other equipment components. For example, during the injection molding process, the temperature of the mold may reach about 100 - 300°C. Without a heat shield, the heat will be transferred to the mold plate of the injection molding machine in large quantities, resulting in high mold plate temperatures, which will affect the performance and service life of the injection molding machine.

Energy saving

By reducing heat loss from the mold to the outside world (e.g. equipment such as injection molding machines), the mold itself is better able to maintain its temperature. This reduces the amount of energy used to heat the mold. In the case of hot runner molds, for example, the power required to maintain the temperature of the mold by the heating element can be reduced with the use of a heat shield, thus reducing production costs.

Improved product quality

For some plastic products or die-casting products that require high dimensional accuracy, it is critical that the mold temperature is stable. The mold heat insulation plate helps to maintain the uniformity of the mold temperature, making the product cooling or curing more uniform during the molding process, and reducing the product's deformation, warping and other defects. For example, in the production of high-precision optical plastic lenses, a stable mold temperature is ensured by the heat shield, which can improve the optical properties and dimensional accuracy of the lenses.

RELATED NEWS

Application Case of Synthetic Stone in Wave Soldering Fixtures

In the electronics manufacturing industry, wave soldering is common, and synthetic stone materials are crucial for wave soldering fixtures.

High Compression Insulation Board: Superior Insulation for Demanding Applications

Industrial Applications and Benefits: Cold Storage and Refrigeration - Application: These boards are utilized in cold storage facilities, refrigerated trucks, and freezer rooms. - Benefits: They provide superior thermal insulation, maintaining consistent low temperatures and improving energy efficiency in refrigeration systems.

Bakelite Sheet: A Versatile Material for Diverse Industrial Applications

The Bakelite Sheet is a high-performance thermosetting plastic known for its excellent electrical insulation, mechanical strength, and thermal stability. This versatile material has found widespread use across various industries due to its unique properties and reliability.

The Versatile Thermal Insulating Board

One of the key performance aspects of the thermal insulating board is its excellent heat - insulating ability. It is designed to minimize the transfer of heat, whether it is to keep heat in or keep it out. This is achieved through its specific composition and structure. The materials used in the board are often poor conductors of heat, such as certain types of polymers or composite materials. This property makes it ideal for applications where temperature control is crucial.

Exploring the Evolution and Impact of Engineering Plastics in Various Industries

Dive into the world of engineering plastics, their innovations, and how they shape industries.

Engineering Plastics: Shaping the Future of Industrial Applications

Explore the innovative world of Engineering plastics and their pivotal role in various industries.

中文版

中文版  ENGLISH

ENGLISH