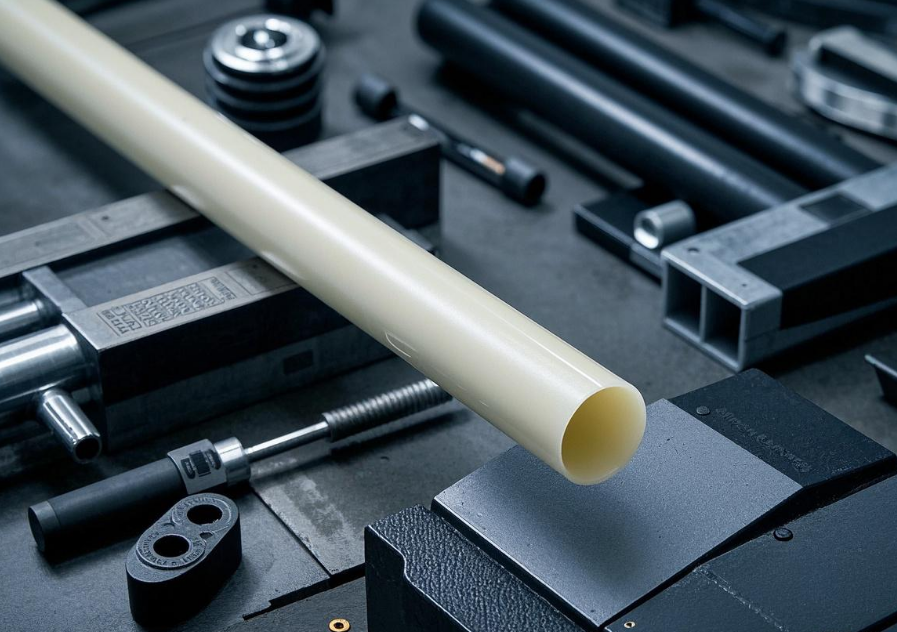

Key material for humanoid robots: PEEK material

Time:

2024-12-12 19:43

Source:

PEEK (polyetheretherketone) material is a high-performance special engineering plastic that has become one of the key materials in the field of humanoid robots due to its excellent mechanical properties, heat resistance, chemical resistance, and lightweight characteristics. The following is a detailed analysis of the application and advantages of PEEK material in humanoid robots:

Basic characteristics of PEEK material

Mechanical properties: PEEK has high strength and rigidity, as well as good toughness, which enables it to maintain stable performance even under high loads and high-speed movements. Its specific strength is close to steel and better than ductile iron, with a density of about 1.3 g/cm ³, which gives it a significant advantage in weight control.

Heat resistance: PEEK material can maintain excellent performance in high temperature environments, such as good tensile strength and creep resistance at 299 ℃. This characteristic makes it suitable for humanoid robot components that require high-temperature resistant operation.

Wear resistance and self-lubricating properties: PEEK material has excellent wear resistance and self-lubricating properties, which can reduce friction and wear when manufacturing components such as joint bearings and gears, and extend their service life.

Chemical stability: PEEK has good resistance to most chemicals and is not easily corroded, ensuring the stable operation of robots in various environments.

Application in humanoid robots

Skeleton and structural components: Due to the high strength and lightweight characteristics of PEEK, it is widely used in the skeleton manufacturing of humanoid robots. The use of PEEK material can significantly reduce the overall weight of robots, improve their maneuverability and flexibility.

Joints and transmission components: The wear resistance and self-lubricating properties of PEEK material make it an ideal choice for manufacturing joints and transmission components, capable of withstanding high loads and maintaining long-term stable motion performance.

Electronic device casing: PEEK's heat resistance and electrical insulation make it an ideal choice for protecting internal electronic components, suitable for manufacturing robot casings.

Market prospects and challenges

Although PEEK material has significant potential for application in humanoid robots, its market promotion still faces some challenges:

Cost issue: The production cost of PEEK material is relatively high, mainly due to the expensive price of its core raw material fluoroketone. This results in PEEK materials being relatively expensive in the market, limiting their large-scale application.

Capacity and technical limitations: Currently, the production process of PEEK is complex, and production capacity is relatively concentrated in the hands of a few international giants. Domestic enterprises mainly rely on imports. This poses certain technological and production capacity bottlenecks for large-scale production.

Market demand growth: With the rapid development of the humanoid robot industry, the demand for lightweight materials continues to increase, and the market prospects of PEEK materials are widely optimistic. Especially after the successful application of PEEK materials by companies such as Tesla, the market's attention to it has significantly increased.

Market demand growth: With the rapid development of the humanoid robot industry, the demand for lightweight materials continues to increase, and the market prospects of PEEK materials are widely optimistic. Especially after the successful application of PEEK materials by companies such as Tesla, the market's attention to it has significantly increased.

PEEK material has shown great potential in the field of humanoid robots due to its excellent performance and lightweight characteristics. However, to achieve large-scale applications, it is necessary to overcome challenges in terms of cost and technology.

RELATED NEWS

Application Case of Synthetic Stone in Wave Soldering Fixtures

In the electronics manufacturing industry, wave soldering is common, and synthetic stone materials are crucial for wave soldering fixtures.

High Compression Insulation Board: Superior Insulation for Demanding Applications

Industrial Applications and Benefits: Cold Storage and Refrigeration - Application: These boards are utilized in cold storage facilities, refrigerated trucks, and freezer rooms. - Benefits: They provide superior thermal insulation, maintaining consistent low temperatures and improving energy efficiency in refrigeration systems.

Bakelite Sheet: A Versatile Material for Diverse Industrial Applications

The Bakelite Sheet is a high-performance thermosetting plastic known for its excellent electrical insulation, mechanical strength, and thermal stability. This versatile material has found widespread use across various industries due to its unique properties and reliability.

The Versatile Thermal Insulating Board

One of the key performance aspects of the thermal insulating board is its excellent heat - insulating ability. It is designed to minimize the transfer of heat, whether it is to keep heat in or keep it out. This is achieved through its specific composition and structure. The materials used in the board are often poor conductors of heat, such as certain types of polymers or composite materials. This property makes it ideal for applications where temperature control is crucial.

Exploring the Evolution and Impact of Engineering Plastics in Various Industries

Dive into the world of engineering plastics, their innovations, and how they shape industries.

Engineering Plastics: Shaping the Future of Industrial Applications

Explore the innovative world of Engineering plastics and their pivotal role in various industries.

中文版

中文版  ENGLISH

ENGLISH