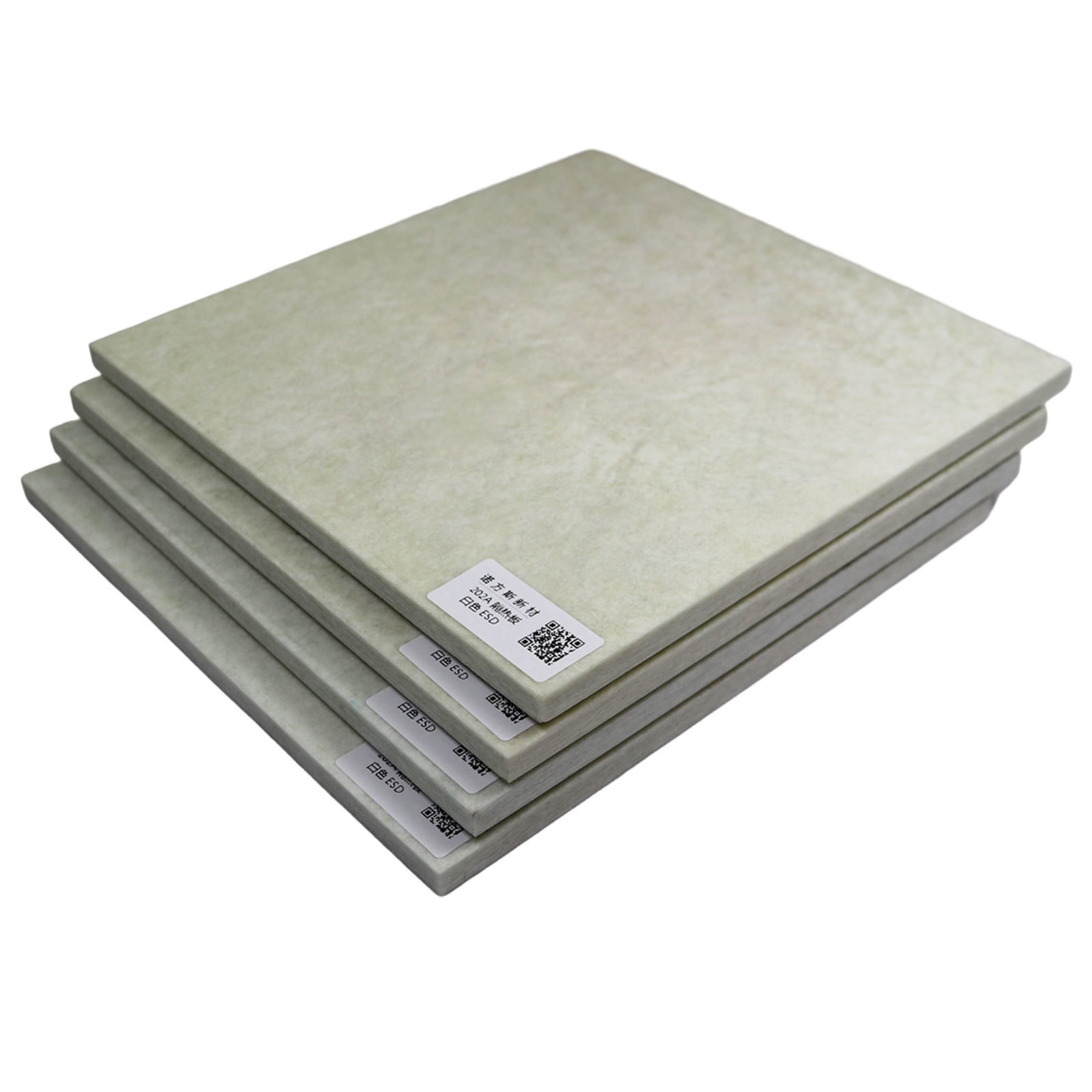

Application of mold heat insulation plate in die-casting industry

Time:

2024-12-12 16:57

Application of mold heat insulation plate in die-casting industry

Die casting molds are used to produce a variety of metal parts, such as automobile engine block, wheel hubs and other aluminum alloy or zinc alloy die-casting products. During the die casting process, the temperature of the metal liquid is very high, generally around 600 - 800℃. The mold insulation plate can prevent the heat brought by the high temperature metal liquid from transferring a large amount of heat to the template and other parts of the die casting machine. This helps to maintain the temperature stability of the die casting mold, so that the metal liquid in the mold can better fill the cavity, while reducing the die casting machine due to thermal stress damage, improve the working efficiency and service life of the die casting machine.

Rubber products industry

In the rubber mold, although the rubber vulcanization temperature is generally slightly lower than the metal die casting and plastic injection temperature, but still need to control the mold temperature. For example, the vulcanization mold in the tire manufacturing process, through the use of heat insulation board can reduce heat dissipation, improve energy efficiency, and to ensure the uniformity of the degree of vulcanization of all parts of the tire, thereby improving the quality and performance of the tire.

Prev

Next

RELATED NEWS

中文版

中文版  ENGLISH

ENGLISH